Security and safety film for glazing

Protection of property and people - Burglary-delay effect

Structural reinforcement of glazing for better protection

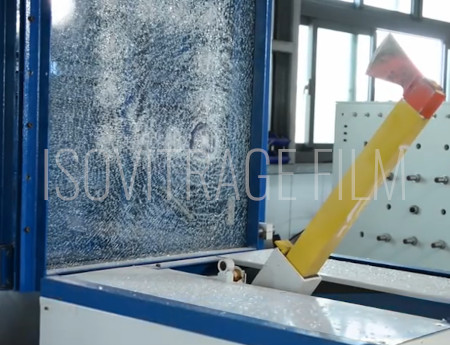

A safety and security film applied to glazing improves the resistance of the glass to break-in attempts and protects property and people against broken glass in the event of the glazing system breaking.

Applied to glazing in high-risk areas, safety films protect against damage caused by broken glass. The adhesive retention force of safety films ensures that broken glass is held together, making the assembly solid in order to prevent as much as possible the detachment of pieces of glass that could injure people or damage objects.

A safety and security film increases the structural resistance of glazing in the event of an impact. The perpendicular thrust exerted on the surface of the glazing is contained by the thickness and rigid design of the safety film. In addition, the strong adhesion to the glazing with the retention of broken glass helps to make the assembly sufficiently resilient against break-in attempts.

With ease of application and low installation cost,

applying safety and security film is the most economical choice

for enhancing the structural strength of existing glazing.

Find the safety and security films of the Arma range

Classification relating to the types of impact on glazing

Classification of impacts leading to glass breakage

- Accidental human impact

- Breaking in

- Extreme weather conditions

- Bomb explosion

- Ballistic impact

Performance Evaluation Characteristics of Adhesive Films

- Elongation

- Tensile strength

- Peel strength

- Breaking strength

- Puncture resistance

- Tear resistance

Standards applicable to safety and security films

1°) EN 12600 standard: Pendulum impact resistance

Pendulum impact test with a mass of 50 kg at different drop heights

Classification according to the breakage mode of the glazing:

Class A : Annealed glass - many pieces of different sizes that break off and are sharp.

Class B : Laminated glass - many pieces of different sizes that do not come off and remain attached to the whole.

Class C : Tempered glass - multitude of small, non-cutting fragments.

2°) EN 356 standard: Resistance to burglary

Test according to 3 methods for classification according to resistance to vandalism and burglary

Anti-vandalism classification P1A to P5A

Test by dropping steel balls (4.11 Kg) on a glazing without them crossing it

Break-in resistance classification P6B to P8B

Sledgehammer and ax impact tests using an automatic mechanism

3°) EN 13501-1+A1 (NF P92-507) Standard : Materials reaction to fire

Test relating to the reaction to fire of construction and development materials. This more comprehensive classification takes into account the fumes released as well as any droplets projected.

Euroclass classification system :

A1 : incombustible

A2 : combustible - non-flammable

B : combustible - non-flammable

C : combustible - hardly flammable

D : combustible - moderately flammable

E-F : combustible - easily flammable

Smoke opacity noted as s (smoke) :

s1 : Amount and rate of smoke release - Low

s2 : Amount and rate of smoke release - Medium

s3 : Amount and rate of smoke release - High

Flaming droplets and debris noted as d (droplets) :

d0 : no debris

d1 : no debris (combustion ≤ 10s)

d2 : not d0, not d1